LNG and NGLs

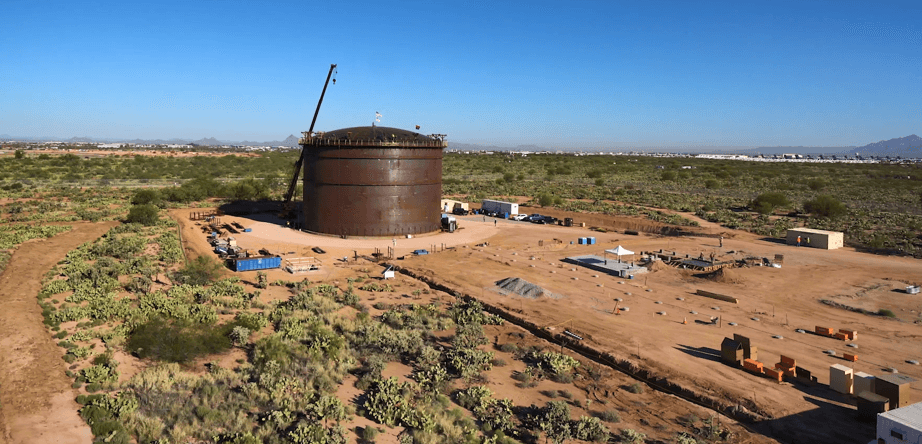

Through its subsidiaries, Matrix is a total solutions provider for LNG (liquefied natural gas) and NGL (natural gas liquids) storage facilities with expertise spanning product conditioning, refrigeration and liquefaction, storage, and ancillary systems. Leveraging our 50+ years of legacy experience designing and constructing cryogenic and refrigerated storage facilities, Matrix offers complete solutions from conception to commissioning and has mastered the seamless transition from FEED to EPC to provide a single-point solution for project execution.

Matrix offers complete life cycle solutions for these facilities by providing condition assessments, engineering evaluations, and full-service facility upgrades and retrofits. Matrix primarily provides these unique service offerings for peak shaving, bunkering, export, and gas-to-power end markets.

LNG Bunkering

As a lower carbon-intense fuel with less post-combustion emissions, LNG is displacing traditional fuels used in maritime transportation. Matrix supports this industry through the design and construction of on-shore LNG production, storage, and ship-loading facilities and has delivered both FEED and EPC solutions to this developing market.

LNG and NGL Export

Increasing international demand for LNG and NGL products necessitates domestic development and expansion of LNG and NGL export facilities. Matrix supports this market from feasibility studies through EPC project delivery and is fully equipped to execute projects domestically and abroad

Gas to Power

Similar to LNG peak shaving facilities, gas-to-power facilities store LNG in a cryogenic state to meet peak demand. The primary difference arises out of the end use for the stored LNG. In gas-to-power facilities, the LNG is used directly for power generation as opposed to feeding a gas transmission or distribution system.

This slight, but important difference, may necessitate different design criteria for systems such as boil-off gas management. Matrix possesses the core competencies to deliver the unique solutions needed to design and construct these facilities.

Matrix has successfully delivered an extensive list of diverse industry-leading LNG and NGL projects and is excited to continue expanding into this division of critical work. Our past and current experience with LNG bunkering, peak shaving facilities, and more have positioned us to see projects through to completion safely, on time, on spec, on budget, and with the quality you expect.

LNG and NGL services:

- Fabrication and construction

- Commissioning

- Life cycle evaluation and condition assessment

- Facility upgrades and retrofits

Conceptual design and feasibility studies, Front End Engineering and Design (FEED) and detailed engineering and procurement offered through Matrix PDM Engineering.

Contact us to learn more.

IN THE NEWS

Matrix Service Company announced that its subsidiary, Matrix NAC, has been awarded the engineering, procurement, and construction of upgrades being made to an existing LNG peak shaving facility that includes a new gas liquefaction system and vaporization system. This project for a large public utility located in the Mid-Atlantic region of the U.S. was awarded and will be taken into backlog in the second quarter of Fiscal 2023.